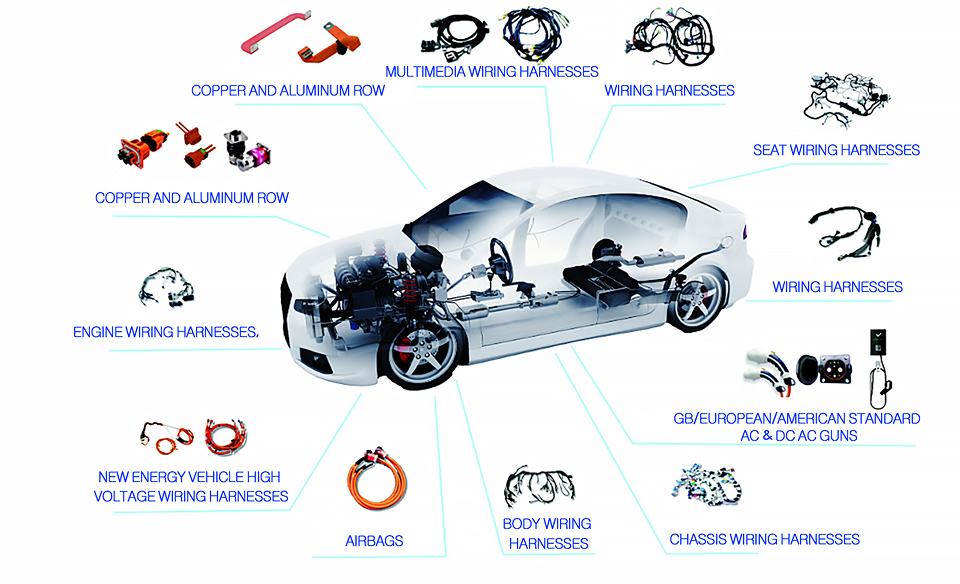

With the rise of new energy vehicles and automotive intelligent network connection, the working environment of automotive wiring harnesses has changed from “low voltage” to “high voltage and large current”. The transformation of working environment has put forward higher requirements for the transmission capacity, mechanical strength, insulation protection, electromagnetic compatibility and anti-interference, body weight and other aspects of automotive wiring harnesses. This also causes the production process requirements and quality requirements of automotive wiring harnesses to change accordingly. The main difference between the new energy vehicle wiring harness and the traditional fuel vehicle wiring harness is the high voltage wiring harness. High voltage wire harness is not only a key part of the high voltage electrical system of new energy vehicles, but also an important guarantee for the safe and reliable operation of new energy vehicles.

Design of high voltage wire harness

1.1 Composition of high voltage harness

High voltage wiring harness mainly includes: high voltage connector, high voltage cable, ground terminal and tie,outsourcing material, tape, heat shrink casing, rubber sleeve, installation support and other auxiliary materials.

1.2 High Voltage connector

According to the function definition, it can be divided into two kinds: small current and large current. The large current is mainly used in OBC, motor, battery and other power systems, while the small current is mainly used in compressor, PTC, battery heating device and DCDC and other functional appliances.

1.3 High voltage cable

High voltage cables are mainly divided into shielded and unshielded cables(bellow) with diameters ranging from2.5mm² to 120mm².

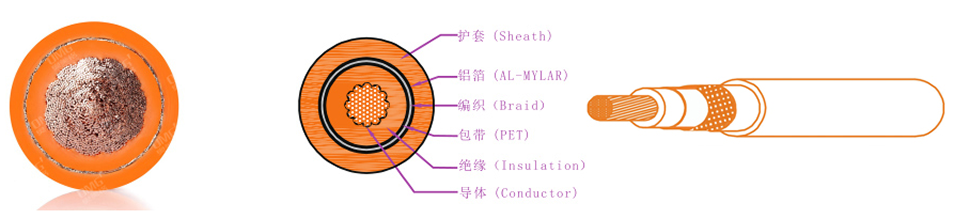

Shielded cable:

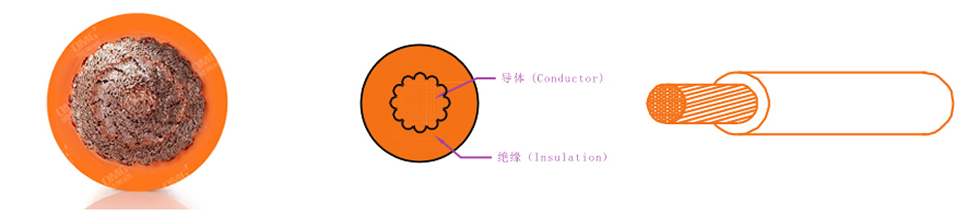

Unshielded cable: